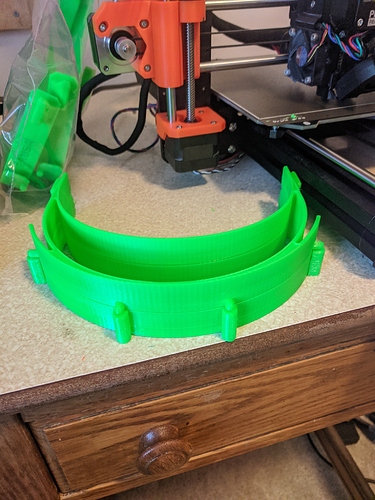

I’m currently printing https://www.prusaprinters.org/prints/27267-prusa-protective-face-shield-rc31-stack-versions/files

I had some good and faster prints with https://www.prusaprinters.org/prints/27477-covid-onx-protective-shield-1620-shields-per-day-o/files I just dropped off a batch of these to Nathan, looking forward to feedback from him when he cleans and assembles.

I thought that this would be a low material option, https://www.prusaprinters.org/prints/27436-protective-face-shield-hyper-speed-remix-rc3hx-5mm. I also gave some of these. They may be too thin. PLA went okay, some challenge to separating afterwards but okay. PETG was too fused and I lost all of the tray while separating.It was a dangerous task.  PLA versions might be worth printing Waiting on feedback.

PLA versions might be worth printing Waiting on feedback.

PLA seemed to work fine. At these thicknesses, shattering was minimal – and I bent the hell out of them, and even twisted. I wouldn’t want to use it for something that will be used for years, but I definitely think PLA is totally useful in our current situation. The only thing I don’t know is PLA’s resilience to many disinfecting agents…given that it’s lactate chain based. But I imagine it’s good as long as its not heat-sterilized?

1 Like

Thanks for the response, and Welcome to the talk site!

https://www.prusaprinters.org/prints/27436-protective-face-shield-hyper-speed-remix-rc3hx-5mm 1

I do not recommend this design at this time. Feedback was given that it’s too thin, and not pleasant on the forehead.

James, are other people in the LMN making shield parts too, besides you and Jody? Im debating how to alter the supply chain if we need to, so more than just me are assembling whole masks.

I haven’t heard who else is printing. I think @RealCarlRaymond is doing the top part. @jody was trying to help with the laser cutter, I don’t think he’s printing.

Anyone else printing?

I am starting to do some printing now in PETG and doing some of the Onx version. These take just under an hour per. I will try a stack of the RC3.1’s tomorrow. I have only part of one spool of PETG but should be able to do quite a few. It is getting to be in short supply online. Will ABS work? It should be OK for temperature and is somewhat flexible.

I also have a roll of surplus clear material that seems much like overhead transparency material. It is about 0.10 mm thick, and is 107 mm wide. That is probably too thin for most situations, but it will work. There is enough to do at least a few hundred shields.Let me know if you have ideas for it.

Oops, that roll is 107cm wide.

@jfahner, if you want to join the larger MSU community that is 3D printing and laser cutting the shield parts, I can ask them to add you. It’s organized by @DrN8PhD, who has made some postings here as well.

We communicate on Microsoft Teams (which you can join just through a web browser) for chat and file sharing. We’re dropping off our frame parts at his house, where he disinfects, assembles, and then takes them to an MSU facility that does the distribution.

Thats about the same thickness as I use to got the top piece I cut it.

https://talk.lansingmakersnetwork.org/uploads/default/original/2X/f/fd82d84baed40276148e914b7ba7da9e05224543.jpeg

I think there’s value to it with the right design for a top piece and possibly a shield

@RealCarlRaymond and @jfahner hit our new website at lib.msu.edu/3DPPE for instructions! We’re trying to streamline ourselves away from the Teams thing as it’s getting overwhelming. If you send your info in the form on our site, we’ll be back shortly with further instructions (meaning, I just finished writing the welcome email today). Also, that site has links to the intros we’re printing(@RealCarlRaymond, did you finish your design?)

Yes, the website is the way to go. Things change fast!

@DrN8PhD I uploaded a .stl and .3mf for a single shield in Communicaion / Files on Teams. I’m working on a 2x2 stacked version now.

@DrN8PhD, I signed up on the website and am printing the second batch of RC3 headbands.

I also have 15 ONX headbands https://www.prusaprinters.org/prints/27477-covid-onx-protective-shield-1620-shields-per-day-o/files like some that @James_the_sparky printed. Do you still want that style, too? I am glad to see that you have standardized on RC2 and RC3. Those take more material and a lot more time, but are a lot more substantial.

@jfahner thanks!!! We will take the onx ones too as they fit the same plastic, but rc2 or rc3 preferably if you’re able to do PETG. Thank you so much for contributing. Send me a PM (or whatever it is here?) and I’ll get you the drop off address. Does that work? You’re local, yes?

Yes, I am local, a few miles from MSU.

I don’t know if we can PM from this platform. Can you access the email from my Maker Form?

I’ve been printing these requested by UofM https://specs.engin.umich.edu/um-face-shield/ however all that I’ve printed won’t do any good if I can’t find the clear plastic, or a way to tie them to your head.

I hate to keep my printer busying printing these if they can’t be used.

@DrN8PhD will be able to help. We stuck with the prusa 4 pin design for now. At this time there isn’t a shortage of face shields cut out or able to be cut in this configuration. With petg a stacked of rc3.1 is working great for me. 8 completed head bands in just over 11 hours.

@zimmer62 this is the best version i have. i use rc3.1 over the rc3.2 because it just works. i use the gcode for mk3s to get those speeds

PLA versions might be worth printing Waiting on feedback.

PLA versions might be worth printing Waiting on feedback.