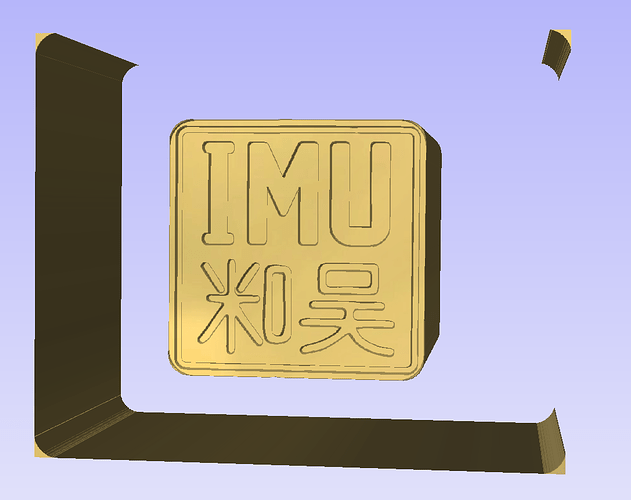

Hey all (though this is particularly aimed at @Bwil415 and @RealCarlRaymond), I’m looking for some feedback on CNC machining some brass. I haven’t done this before! ![]()

Basically, I am trying to take the below block, about 2.5" x 2" x 1.65"

And machine out a smaller block, 1.25" x 1.25" x 1.65"

To accomplish this, I am thinking I will remove the clamp on the bed of the machine and use Blake’s blue tape and super glue trick on a piece of sacrificial aluminum, more or less as shown in the first image.

I am not worried about the etching on the face of the design, but I am concerned about the rough removal of the material around the finished product.

Right now, I intend to use the following settings to accomplish that step:

1/2" Carbide end mill bit qualities:

-3 flutes

-1" flute length

-3" overall length

CAM settings:

-9000rpm

-48ipm reed rate

-15ipm plunge rate

-1/4" pass depth (for a total of 7 passes over 1.65")

So here is where I am looking for feedback, in particular:

One issue I foresee with this is that in order to achieve my “pocket” depth of 1.65", I will have to expose the shank to the material I am cutting, since the flutes are only 1" in length. I am not sure if this is an issue, since the machine will be cutting from the outside in, so it would never be “surrounded” by material.

The other issue is the matter of of bed adhesion. I don’t intuitively know when a piece has too little surface area on the bed in order to use the blue tape and glue trick effectively. My block is taller than what Blake milled in his example post. If I go for some other mounting solution, I don’t have an idea of what would help me achieve my desired effect. Is it something you would try?

Any thoughts? Does it all look kosher? Need any more information? If anyone would like to help me look it over in person this weekend, that would be appreciated as well.

Thanks for taking the time to read!