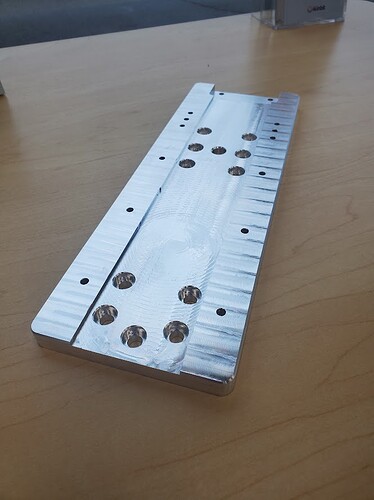

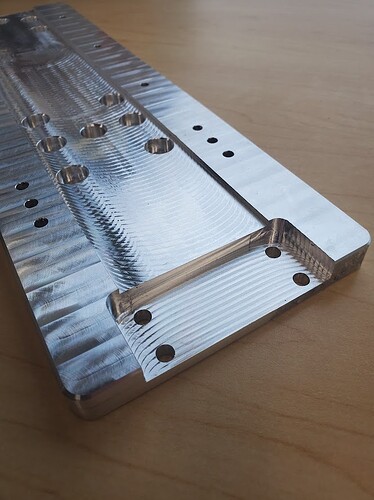

Just wanted to share a work-holding technique which can be used in a variety of situations. It’s commonly used on CNC machines where precision or rigidity can be sacrificed for convenience and access to the entire perimeter and top of a part. It also generally requires a piece that is flat on one side with a large surface area relative to height/thickness. Here’s how it works:

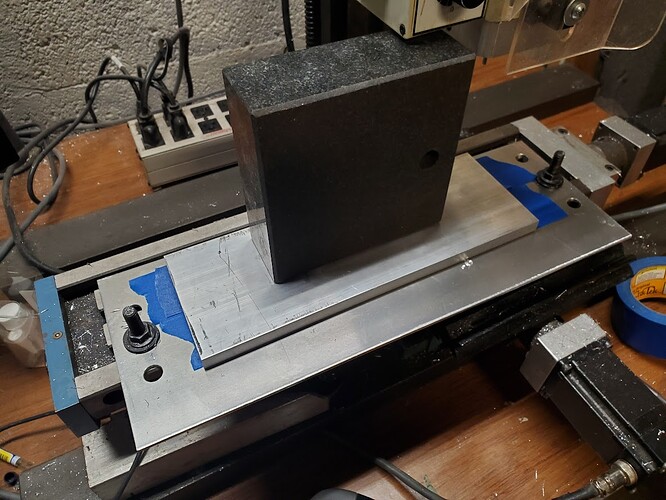

Use large pieces of painters tape on the bottom face of the work piece and corresponding pieces on the surface to which it will be fixed. Apply super glue (cyanoacrylate) to the tape and stick the two taped surfaces together with some clamping force. In this case, I am using a sacrificial piece of aluminum sheet bolted to the mini mill table to prevent me from cutting into the machine and giving the ability to shift the work around after it is glued. The work piece is some 1/2in thick aluminum bar stock.

The tape acts as a release film, so once machining is done it can be peeled off easily. This method can be used on mills, CNC routers, planer/router sleds, jigs etc. I used it to machine the perimeter, pockets, holes and front face of this part in one setup. I left the piece of sacrificial aluminum with the mini mill if anyone else wants to use it.