Today we got the Dake horizontal metal cutting bandsaw back in shape. The hydraulic cylinder wouldn’t hold well, so it was hard to hold the arm up, and let the blade fall too fast for a good cut. With a little help from @jody, it’s working much better now. There is much better control over the rate of gravity feed. It can now hold the moving arm up in the air indefinitely.

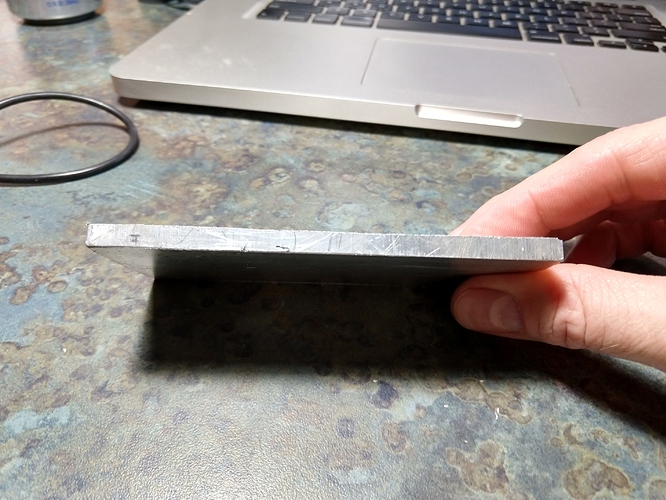

A test cut on a 4.5" tall piece of material came out nicely parallel. There was no detectable drift in the blade. Difference in thickness is less that .1mm between the two ends.

The blade seems fine. I think all the trouble came from the hydraulic cylinder.

For a good cut, make sure to move the adjustable blade guide (in front of the movable vise jaw) to expose as little of the blade as needed to make the cut. Then also check that the arm can swing all the way down without the guide bumping into the vise jaw. Don’t let the arm swing down too fast. Slow and steady wins the race. And of course the material (steel vs. aluminum) and the width govern how fast you can go.

Now I’m going to pack up this piece and send it off to NIST, with a note that says “Here’s what parallel is; please update your standard.”