We got the spindle back from the motor doctor, and tonight I gave it a speed test. It did much better than before. The repair shop was not very helpful, however. They only changed the grease in the bearings, and re-tightened the collar. Possibly the collar was not tightened to the right torque before, given that it came off in use. Maybe that explains the previous trouble, but I can’t be sure. We do know that the current bearings are still not the highest quality available. I can’t say how well they will do.

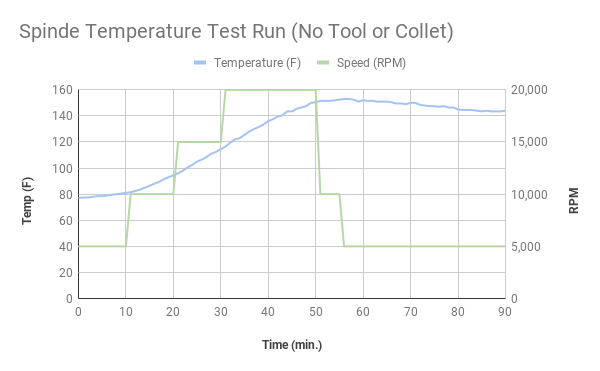

I gave it a good 90-minute workout, stepping the speed from 5,000 RPM up to 20,000, where it ran for 20 minutes. The peak temperature was 153F, which is hot but still below the 160F maximum specified in the manual. In @Joe’s previous test, the temperature spiked up immediately, and he shut it down to avoid overheating. (We measured the temperature at the neck above the collet, on the grey paint. Tonight I noticed that the temperature on the body of the motor was a few degrees higher than the neck after running for a long time, so it got uncomfortably close to the maximum temperature.)

It’s available for careful use. Keep the speed no higher than 15,000 RPM. We normally run the 1/4" straight bit at 12,000 RPM, and larger bits (like the 2" bit for resurfacing) much slower. Use the infrared thermometer to keep an eye on the temperature at the neck. Stop if the temperature exceeds 150F.

Please report anything unusual (high temps, weird noises, etc.) that you encounter. If everything goes well, you can report that, too.