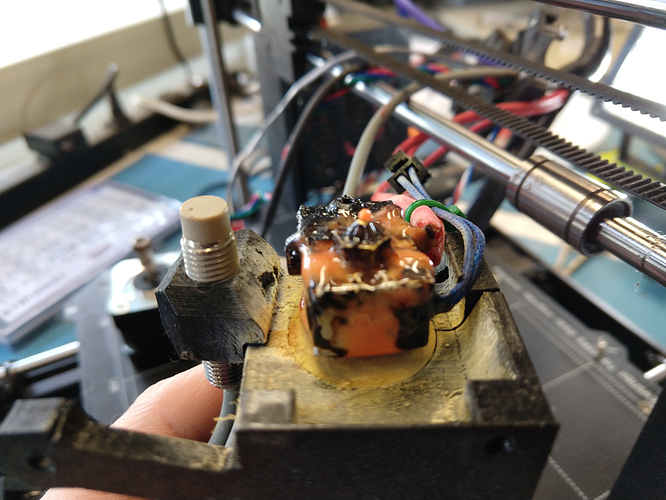

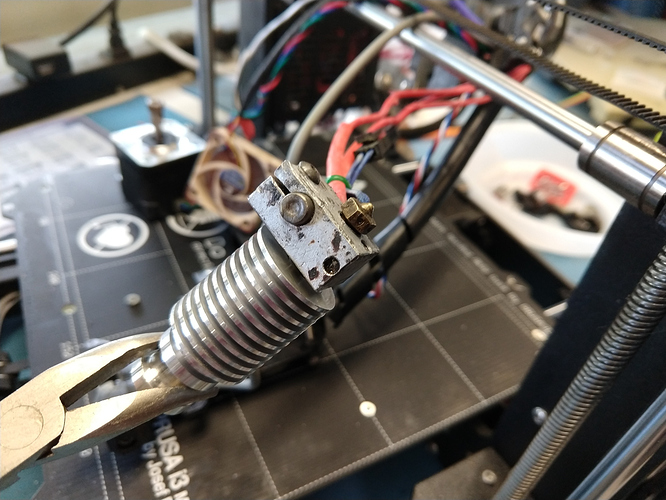

I continued to have trouble with the 3D printer. A “MINTEMP” error would show up intermittently with the original thermistor, and with a replacement I bought. Then I got a pair of used, working, hot ends from @DrN8PhD from the MSU face shield printing group, and transplanted one of them.

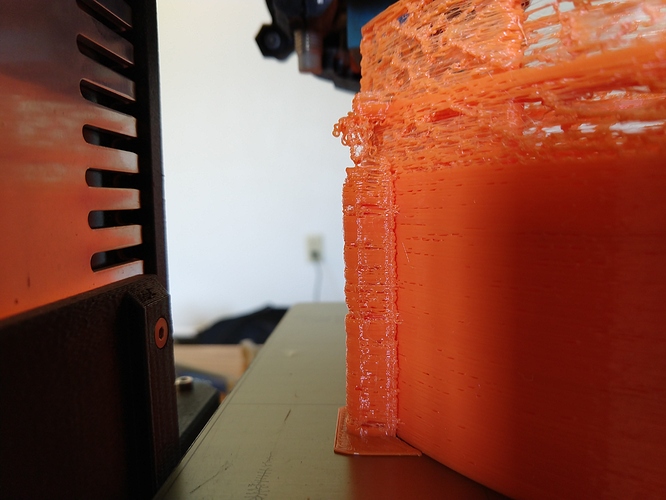

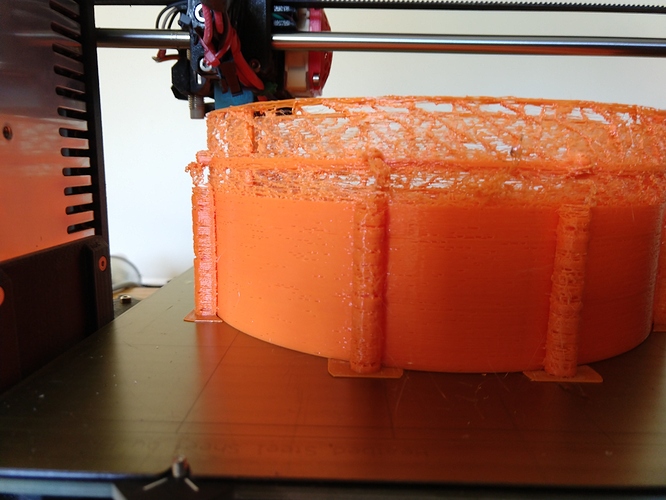

At first it looked good, but after about 3 hours of printing I got another MINTEMP error. Luckily that happened right after finishing the second in a stack of face shields, so I had two usable ones with only a layer or two of wasted plastic.

But now it’s clear the problem probably isn’t the thermistor itself or the cable. I thought it might be bad soldering on the PCB connector, so I opened up the box and got the board out. It looked fine, but I touched up the joints on the connector anyway. It’s lead-free solder, which is not as fun to work with. I put it all back together, but then I got a quick MINTEMP error. At least it was quick.

Then I wondered what else it could be. Firmware? There happened to be a new version of the firmware for the printer released on May 19. And the release notes mentioned that a couple of MINTEMP issues were fixed. Aha! While I was downloading and installing, I read further and saw that the fix was that when you get a MINTEMP error, it now tells you which thermistor is the problem. Which was a headslapping moment. There are two thermistors; one in the nozzle and one under the bed. I had been assuming that it was the one in the head. Has it been the other one all along?

After the update and starting a test print, I soon got an error, but this time it said “MINTEMP bed”. So it was the bed thermistor after all. It’s mounted under the bed with a big piece of Kapton tape. I wiggled out its cable and found a definitely dodgy section under the bed. Rather than patch the cable, and risk goofing up the thermistor (the heated bed and thermistor are sold as an assembly, for $85.00), I opted to just tape down the loose cable under the bed with some more Kapton.

For the moment, that seems to have fixed it. I’ve been printing for several hours and things look great. The nozzle isn’t leaking, and for now MINTEMP has been kept at bay.

Of course I realize that by writing all this down and clicking “Reply” in a moment, I will be jinxing the whole thing. I accept the risk.